As we continue moving closer to completion of the Swartz Hall renewal, one of the tasks underway on the project site is the installation of restored and replicated millwork. The millwork includes wall panels, doors, trim, cabinets, and more. These items are typically crafted elsewhere and brought on site to be installed.

For our project, we chose to work with Mark Richey Woodworking, based in Newburyport, Massachusetts. The local company has a reputation as one of the best woodworkers in the country, and because of their workers’s significant level of knowledge, we knew we were going to get consistency, quality, and products that look good.

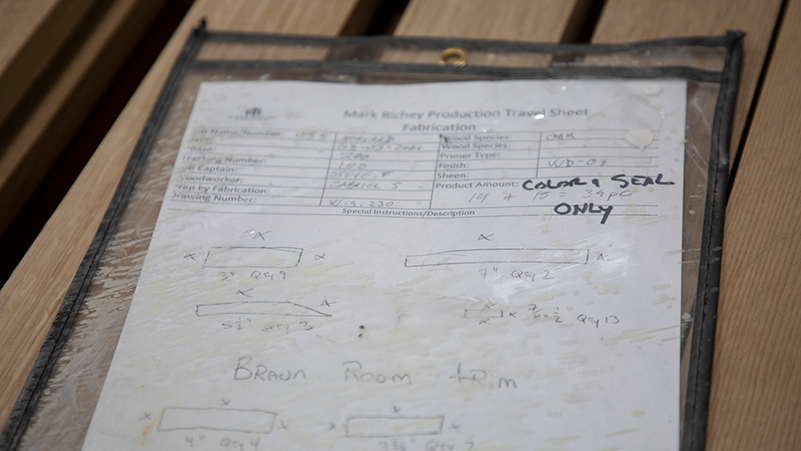

At the company’s massive shop in Newburyport, workers are busy creating these items with care and attention to detail. As you can see in the pictures below, workers are assembling and finishing wall panels that will be used throughout the renewed building, including in the new multifaith space, trim that will be installed in the Braun Room, and vertical fins that will be attached to the floor-to-ceiling windows in the multipurpose space. (I’ve also included a rendering of that space so you can get a sense of what the fins will look like in place.) The wood being used in the new areas of Swartz Hall is solid red oak and rift red oak. White oak is being used in the chapel space and other pre-existing areas to better match the millwork that was already there.

One special aspect of the millwork is the attention to the doors of the building. The old doors were removed and taken to the Newburyport shop where they underwent a unique process during which they were scanned to determine their profile. The company then cut new knives specifically to remake and capture the detail of the doors. As for their stain, the original doors had been coated over countless times during the life of the century-old building, meaning that a lot of the texture and grain that was originally there was gone. It also means the doors were darker than what they would have looked like when they were originally installed 100 years ago. In the pictures below you can see the new, replicated interior doors and how the stain treatment was made in an effort to have the doors match as close as possible what they would have looked like when the building was first constructed. You can also see the exterior doors waiting to be worked on as well.

Beyond their skill and ability, we wanted to work with Mark Richey because the company has a reputation as one of the country’s greenest manufacturers. It reduces its waste by using leftover wood chips, scraps, and sawdust to fuel its clean burning biomass furnace, replacing more than 10 million cubic feet of natural gas per year. Its 292-foot-tall wind turbine generates 60 percent of the total electricity needed to power the company’s operation. That, combined with its solar array, boosts the company’s onsite renewable energy production to nearly 100 percent. What’s more, the company is certified by Massachusetts as a Minority/Woman-Owned Business Enterprise.

The partners that contribute work to this project are vitally important to us, not only through the quality of their work, but because of the values they share with HDS. We’re excited to have Mark Richey contribute to this project and are even more excited to see the finished product throughout our new, true campus center.

Site work. Interior finish work continues, including painting, door and hardware installation, wall framing, and tiling. Irrigation work on the east and west lawns is ongoing. Window installation in the Braun Room is ongoing. Mechanical, electrical, and plumbing work also continues throughout the building, including the stack wing. Installation of a second elevator in the multipurpose addition nears completion. Masonry around the interior fireplace continues. Installation of concrete stairs in the courtyard is expected to begin. Carpentry, concrete, masonry, and finishing work continues in the library. All activities are subject to change based on weather or other circumstances.

—Ralph